ANYBOT

PIRO VISION

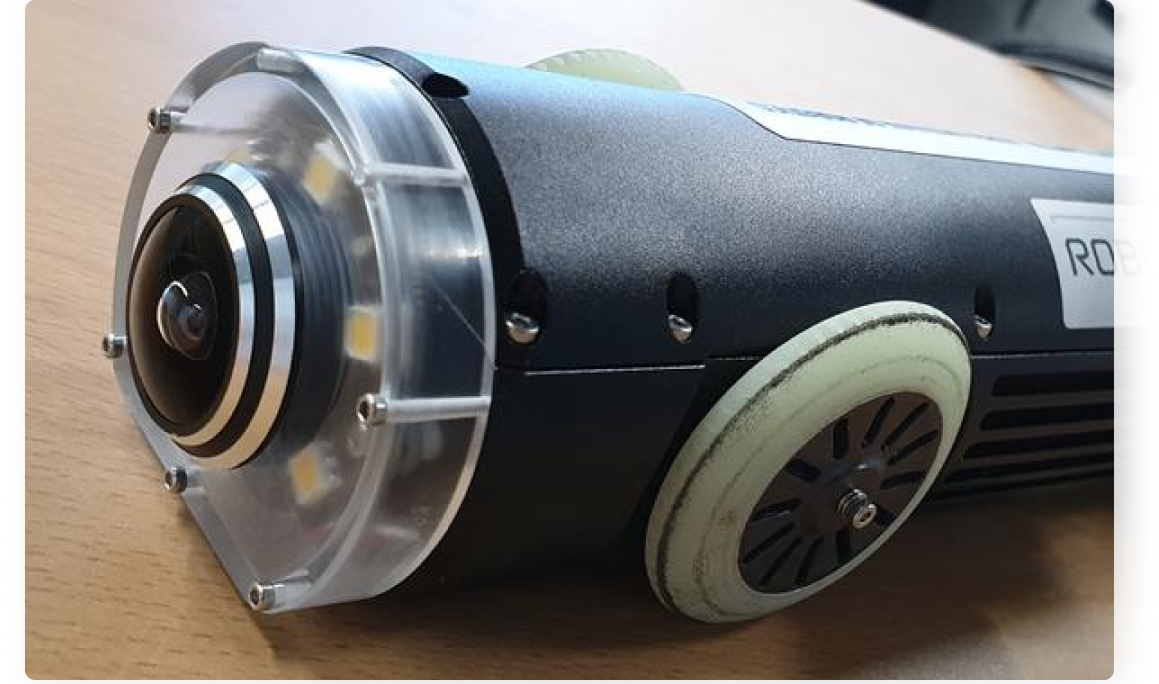

Pipe Vision Inspection Robot

Welding spatter pressing Inspection

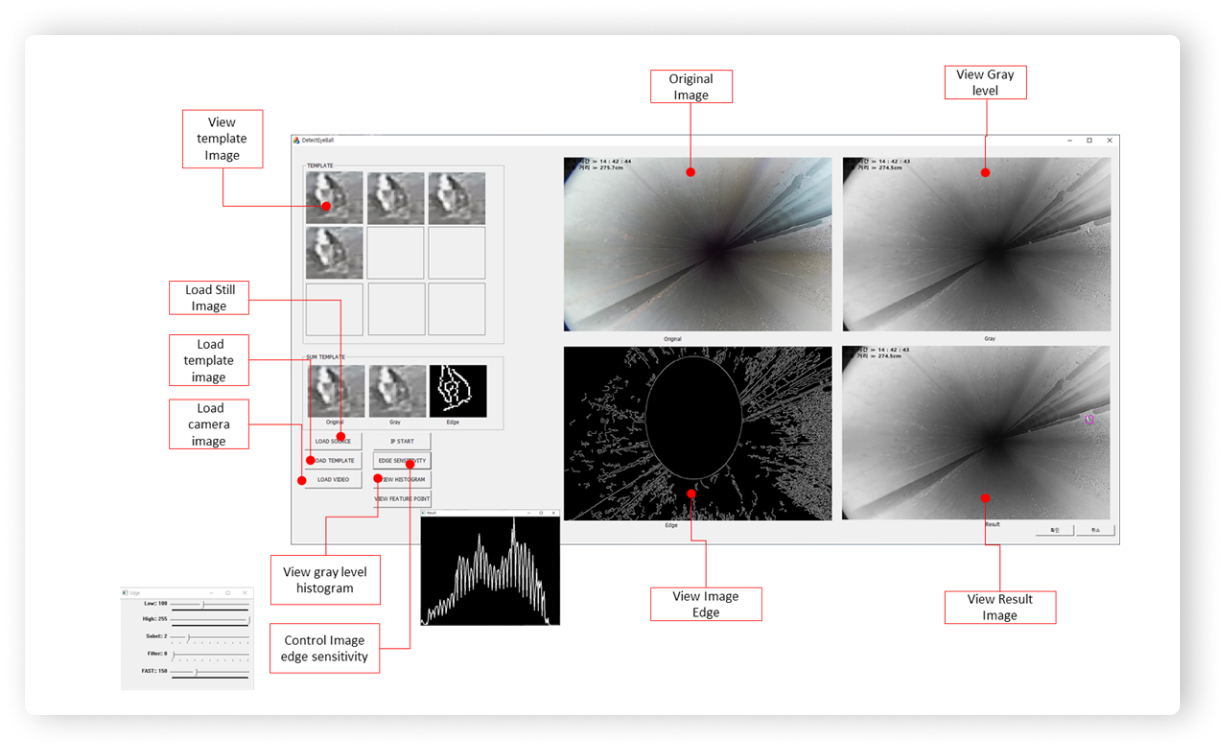

- Inspection of welding spatter pressing based on real-time vision recognition algorithm

Position Information Extraction

- Extraction of weld spatter pressing position information : distance, weld bead reference angle

Small diameter pipe Driving

- Driving small diameter pipe from 60mm to 89mm

- 01

- PIRO VISION

- PIRO VISION is a robot that inspects welding spatter pressing inside pipes using a compact pipe-traveling robot platform.

- 02

- Core Technologies

- Small-Diameter Pipe Driving : Driving small-diameter pipes from 60mm to 89mm.

- Inspection of Welding Spatter Pressing : Inspection of welding spatter pressing based on a real-time vision recognition algorithm.

- Welding Spatter Pressing Detection Technology : Detection and digitization of welding spatter pressing (1~3mm).

- Position Information Extraction Technology : Technology to locate anomalies based on pipe distance and weld bead angles.

- 03

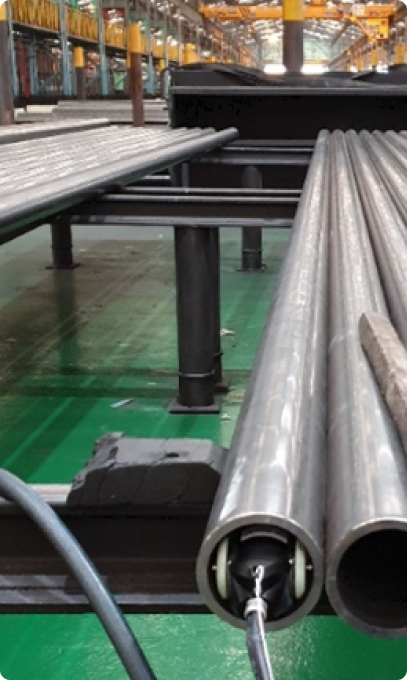

- Application

-

Small Pipe Inspection

Inspection and defect analysis of small-diameter pipe interiors. -

Inspection of Welding Spatter Pressing

Detects welding quality and pipe condition issues to enhance maintenance efficiency. -

Position Information Analysis

Reporting and managing pipe conditions through internal distance and angle data.