ANYBOT

JCOE PCS ROBOT SYSTEM

Pipe End Tab Cutting and Internal Welding Bead Shaving Robot System

Pipe-End Tab Detection Technology

- Contact-Based Sensing Technology for Extracting Cutting Position Information of Pipe-End Tabs

Pipe-End Tab Plasma Cutting

- Plasma Cutting of Pipe-End Tabs Attached to the Front and Rear Ends of Pipes

Weld Bead Recognition Technology

- Non-Contact Sensing Technology for Detecting Weld Bead Shapes Inside Pipes

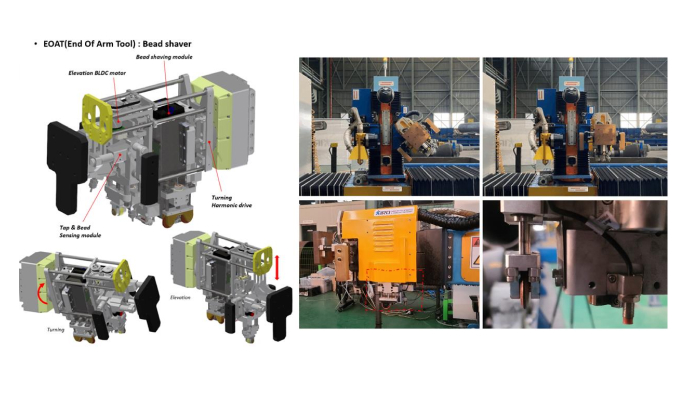

Internal Weld Bead Shaving

- Precision Cutting Technology to Meet API Specifications

- 01

- JCOE PCS ROBOT SYSTEM

- JCOE PCS ROBOT SYSTEM is a robotic system designed to automate the removal of pipe-end tabs and the internal weld bead shaving process in large pipe manufacturing, enhancing work quality and efficiency.

- 02

- Key technology

- Non-Contact Real-Time Sensing Technology : Real-time detection of weld bead shapes and conditions.

- Motion Control Based on Sensing Data : Optimization of robot movements using sensing data.

- Plasma Cutting and Precision Shaving Technology : Automated pipe-end tab removal and weld bead shaving to meet API specifications.

- Adaptability to Various Pipe Sizes : Supports a wide range of pipe diameters (D 457mm ~ 1,625mm) and thicknesses (7.9T ~ 50.8T).

- 03

- Application

-

JCOE Steel Pipe Manufacturing Process

Automates pipe-end tab removal and internal weld bead shaving. -

Steel Pipe Quality Management

Ensures API compliance and improves steel pipe quality. -

Operational Efficiency

Replaces manual work to enhance processing speed and productivity.