ANYBOT

PIRO GRINDING

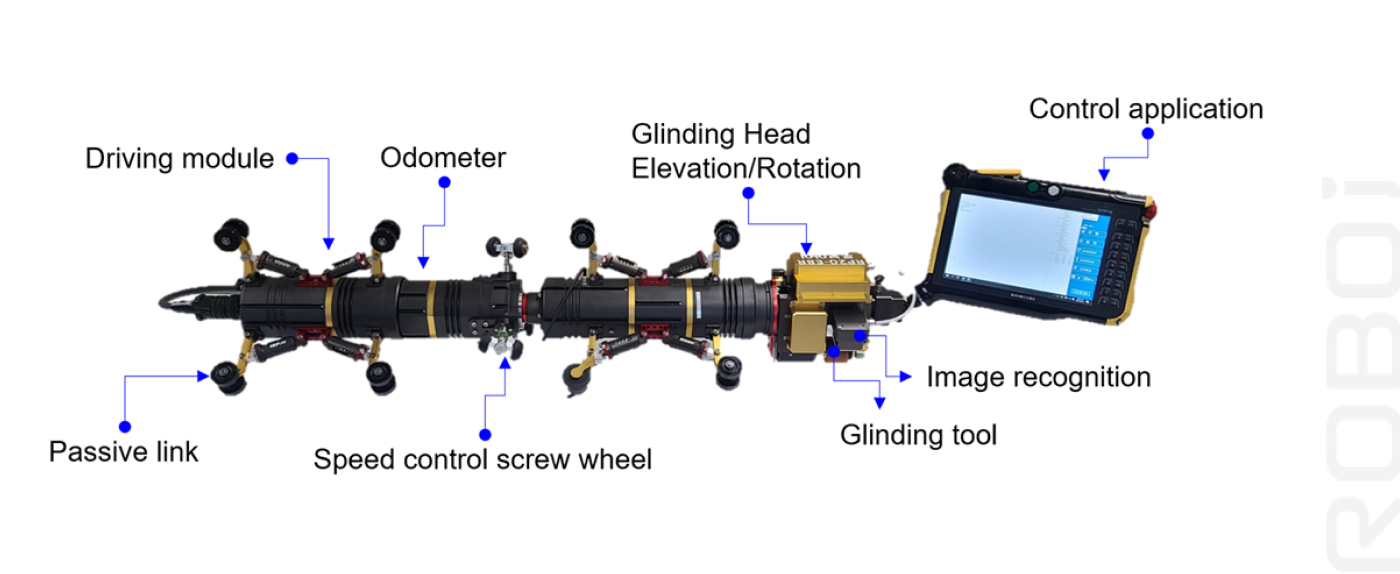

Pipe Eye-Ball Vision Inspection and Grinding Robot

Spiral Turning Drive

- Based on a spiral turning mechanism, enables helical driving inside pipes for uniform inspection and grinding.

Weld Spatter Pressing Inspection

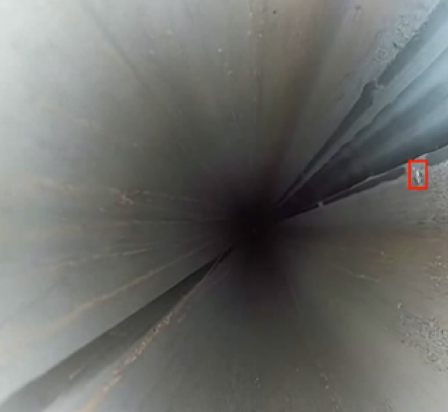

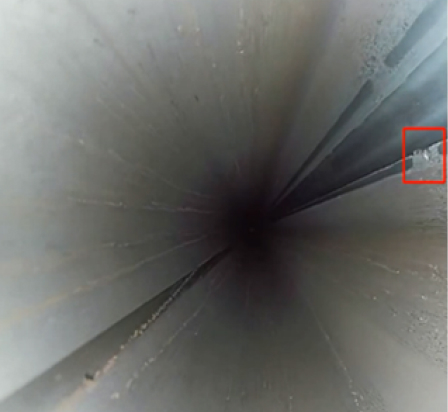

- Inspection of welding spatter pressing based on real-time vision recognition algorithm

Position Information Extraction

- Extraction of weld spatter pressing position information : distance, weld bead reference angle

Automated Grinding Function

- Automatic grinding using a grinding module based on welding spatter position information.

- 01

- PIRO GRINDING

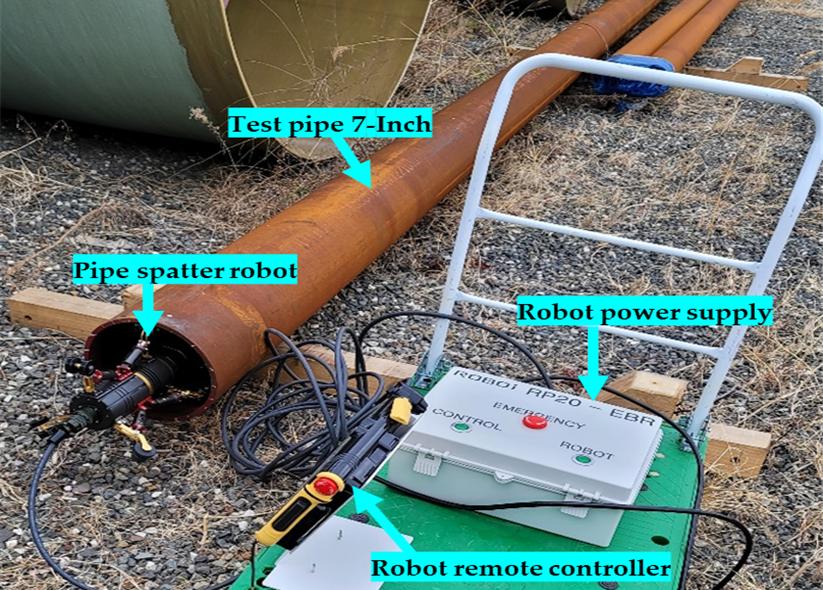

- PIRO GRINDING is a robot that drives inside pipes using a multi-link mechanism structure and a spiral turning mechanism. It detects welding spatter pressing through vision recognition technology and grinds the detected spatter pressing automatically using a grinding module based on its position.

- 02

- Key technology

- Multi-Axis Pipe-Driving Robot Platform : Driving technology adaptable to pipe diameters of D 175mm to 250mm.

- Spiral Turning Mechanism : Drives inside pipes in a spiral motion to enable uniform inspection and grinding.

- Vision-Based Welding Spatter Inspection Technology : Detects welding spatter pressing and extracts position information using vision algorithms.

- Automated Grinding Module and Precision Motion Control : Performs automated grinding based on Spatter location data.

- 03

- Application

-

Fuel & Oil Pipeline

Removal of Welding Spatter Pressing and Early Detection of Weld Defects -

Energy Steel Pipe Quality Inspection

Vision-based inspection of welding spatter pressing and other defects. -

Internal Pipe Grinding

Automatically grinds welding spatter pressing issues after vision inspection to improve steel pipe quality. -

Long-Distance Pipe Maintenance

Enables efficient inspection and grinding for pipes up to 20m in length.